US Auto Suppliers: Navigating the EV Transition Challenges & Opportunities

US auto suppliers face key challenges such as adapting to new technologies, managing supply chain disruptions, and meeting evolving regulatory standards during the transition to electric vehicles, but significant opportunities exist in innovation, diversification, and strategic partnerships to thrive in the EV market.

The shift towards electric vehicles (EVs) is reshaping the automotive landscape, presenting both challenges and opportunities for US auto suppliers. Navigating this transition successfully is crucial for their long-term viability and growth. Understanding what are the key challenges and opportunities for US auto suppliers in the transition to electric vehicles is vital for stakeholders across the industry.

Understanding the Electric Vehicle Transition

The automotive industry is undergoing a monumental shift, driven by increasing environmental concerns, technological advancements, and evolving consumer preferences. Electric vehicles are no longer a niche market but a rapidly growing segment poised to dominate the future of transportation. This transition presents both challenges and opportunities for US auto suppliers.

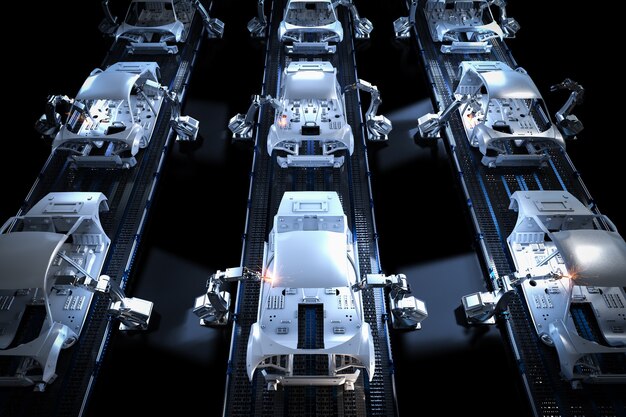

Traditional auto suppliers, accustomed to producing components for internal combustion engines (ICE), must now adapt to a new reality where electric powertrains, battery systems, and advanced electronics are at the forefront. This requires significant investments in research and development, new manufacturing processes, and workforce training.

The Pace of EV Adoption

The speed at which EVs are being adopted varies across different regions and market segments. Factors influencing this pace include government policies, charging infrastructure availability, and consumer acceptance. Understanding these dynamics helps suppliers make informed decisions regarding their investments and strategic priorities.

Impact on Traditional Components

The shift to EVs means a decline in demand for many traditional ICE components, such as fuel injectors, exhaust systems, and transmissions. Suppliers specializing in these areas face the challenge of diversifying their product portfolios or finding new applications for their existing expertise.

For example, a company previously focused on manufacturing fuel pumps might explore opportunities in thermal management systems for EV batteries. This transition requires a strategic vision and a willingness to embrace new technologies.

Key Challenges Facing US Auto Suppliers

Several critical challenges confront US auto suppliers as they navigate the EV transition. These challenges range from technological hurdles to supply chain complexities and regulatory pressures. Overcoming these obstacles is essential for maintaining competitiveness and securing a sustainable future.

The need to invest in new technologies and adapt to evolving market demands are some of the most pressing considerations for companies operating in this sector.

- Technological Adaptation: Developing expertise in EV-related technologies, such as battery management systems, electric motors, and charging infrastructure.

- Supply Chain Disruptions: Managing disruptions in the supply of critical materials, such as lithium, cobalt, and nickel, which are essential for EV battery production.

- Workforce Training: Upskilling and reskilling the workforce to handle the complexities of EV manufacturing and maintenance.

- Regulatory Compliance: Adhering to increasingly stringent environmental regulations and emissions standards.

These challenges require strategic planning, collaboration, and a proactive approach to innovation and adaptation.

Technological Adaptation and Innovation

The transition to EVs demands significant technological adaptation from auto suppliers. They must invest in research and development to acquire expertise in new areas and develop innovative solutions that meet the unique requirements of electric vehicles.

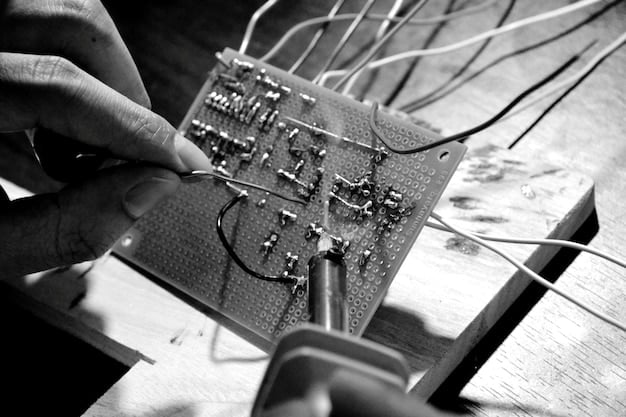

This includes mastering technologies related to battery systems, electric motors, power electronics, and advanced driver-assistance systems (ADAS). Suppliers must also develop the capabilities to integrate these technologies into their existing product offerings.

Battery Technology

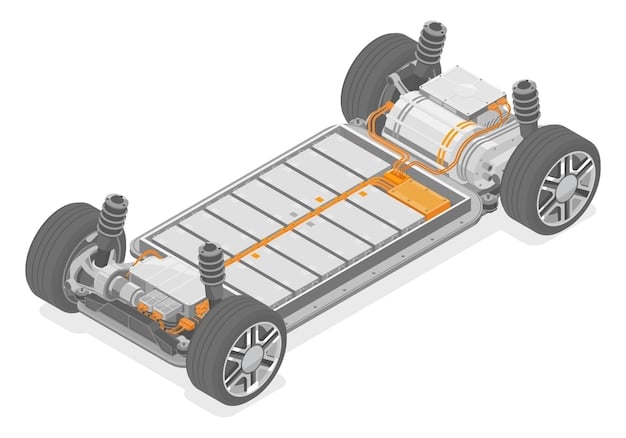

Batteries are a critical component of EVs, and their performance directly impacts the vehicle’s range, charging time, and overall efficiency. Suppliers must invest in battery technology, exploring different chemistries, cell designs, and thermal management systems.

- Cell Chemistry: Researching and developing advanced cell chemistries, such as solid-state batteries, to improve energy density and safety.

- Module Design: Optimizing battery module designs to enhance thermal performance and reduce weight.

- Battery Management Systems (BMS): Developing sophisticated BMS to monitor and control battery performance, ensuring optimal efficiency and longevity.

Investing in battery technology is not just about improving performance, but also about ensuring safety and reliability, as these are critical factors for consumer acceptance and market adoption.

Electric Motor Development

Electric motors are another key component of EVs, responsible for converting electrical energy into mechanical power. Suppliers must develop high-efficiency motors that are compact, lightweight, and cost-effective.

This requires expertise in motor design, materials science, and manufacturing processes. Suppliers must also develop the capabilities to integrate motors with power electronics and control systems.

Supply Chain Management and Material Sourcing

The EV transition introduces new complexities to the automotive supply chain. Sourcing critical materials, such as lithium, cobalt, and nickel, is a major challenge, as these materials are often concentrated in specific regions and subject to geopolitical risks. Suppliers must diversify their sourcing strategies and build resilient supply chains to mitigate these risks.

Effective supply chain management is crucial for ensuring a stable supply of materials, controlling costs, and maintaining production schedules. This requires collaboration with suppliers, strategic partnerships, and investments in logistics and inventory management.

Diversification of Sourcing

Relying on a single supplier for critical materials can expose auto suppliers to significant risks. Diversifying the supply base and exploring alternative sources of materials is essential for ensuring a stable supply and mitigating disruptions.

- Geographic Diversification: Sourcing materials from different regions to reduce reliance on specific countries or regions.

- Supplier Partnerships: Building strong relationships with multiple suppliers to ensure access to critical materials.

- Alternative Materials: Exploring alternative materials that are more readily available and less subject to geopolitical risks.

By diversifying their sourcing strategies, auto suppliers can reduce their vulnerability to supply chain disruptions and ensure a more resilient supply of critical materials.

Building Resilient Supply Chains

Beyond diversification, building resilient supply chains requires investing in logistics and inventory management. Suppliers must develop the capabilities to track materials throughout the supply chain, anticipate potential disruptions, and implement contingency plans.

This includes investing in technology, such as blockchain, to improve transparency and traceability, as well as establishing strategic partnerships with logistics providers to ensure efficient transportation and storage.

Workforce Training and Development

The EV transition requires a workforce with new skills and expertise. Auto suppliers must invest in training and development programs to upskill and reskill their employees, preparing them for the challenges of EV manufacturing and maintenance.

This includes training in areas such as battery technology, electric motor repair, and advanced electronics. Suppliers must also develop programs to attract and retain talent, creating a skilled workforce that can drive innovation and growth.

Upskilling and Reskilling Programs

Upskilling and reskilling programs are essential for equipping existing employees with the skills they need to succeed in the EV era. These programs should cover a wide range of topics, from basic электро mechanics to advanced battery technology.

- Technical Training: Providing hands-on training in EV-related technologies, such as battery repair and electric motor maintenance.

- Online Courses: Offering online courses and certifications to allow employees to learn at their own pace.

- Mentorship Programs: Establishing mentorship programs to pair experienced employees with those who are new to EV technology.

By investing in these programs, auto suppliers can ensure that their workforce has the skills needed to support the EV transition.

Attracting and Retaining Talent

Attracting and retaining talent is crucial for building a skilled workforce that can drive innovation and growth. Auto suppliers must offer competitive salaries and benefits, as well as creating a positive work environment that fosters creativity and collaboration.

This includes investing in employee development programs, providing opportunities for career advancement, and recognizing and rewarding employee contributions.

Seizing the Opportunities in the EV Market

While the EV transition presents significant challenges, it also offers immense opportunities for US auto suppliers. By embracing innovation, diversifying their product portfolios, and building strategic partnerships, suppliers can thrive in the evolving automotive landscape.

The shift to EVs is creating new markets and business models, providing suppliers with the chance to expand their customer base and increase their revenues. The companies that succeed will be those that are proactive, agile, and willing to embrace change.

Innovation in EV Technologies

The EV market is ripe with opportunities for innovation. Auto suppliers can develop new technologies that improve the performance, efficiency, and safety of EVs.

- Charging Solutions: Developing innovative charging solutions that reduce charging time and improve convenience.

- Lightweight Materials: Using lightweight materials to reduce vehicle weight and improve energy efficiency.

- Smart Technologies: Integrating smart technologies, such as connected car features and autonomous driving capabilities, into EVs.

By investing in innovation, auto suppliers can differentiate themselves from competitors and capture a larger share of the growing EV market.

Strategic Partnerships and Collaborations

Building strategic partnerships and collaborations is essential for success in the EV market. Suppliers can partner with other companies to share resources, expertise, and market access.

| Key Point | Brief Description |

|---|---|

| ⚡ Technological Adaptation | Developing expertise in EV-related technologies like batteries and motors. |

| 🔗 Supply Chain Management | Diversifying material sourcing and building resilient supply chains. |

| 🧑🎓 Workforce Training | Upskilling and reskilling employees for EV manufacturing and maintenance. |

| 🤝 Strategic Partnerships | Collaborating with other companies to share resources and expertise. |

Frequently Asked Questions

▼

The main challenges include adapting to new technologies, managing supply chain disruptions, workforce training needs, and adhering to evolving regulatory standards for EVs.

▼

They can invest in R&D, partnering with tech firms, and developing in-house expertise in battery systems, electric motors, and power electronics to stay competitive.

▼

Opportunities include innovation in charging solutions, lightweight materials, smart technologies, and diversification into new markets within the EV ecosystem.

▼

Workforce training is critical for upskilling and reskilling employees in EV manufacturing and maintenance, ensuring they can handle the technological complexities of EVs.

▼

Strategic sourcing helps secure a stable supply of critical materials like lithium and cobalt, reducing reliance on single suppliers and mitigating risks from geopolitical factors.

Conclusion

The transition to electric vehicles presents both formidable challenges and exciting opportunities for US auto suppliers. By embracing technological advancements, proactively managing supply chain complexities, investing in workforce development, and fostering strategic partnerships, these suppliers can not only navigate the EV revolution but also thrive in the evolving automotive landscape.